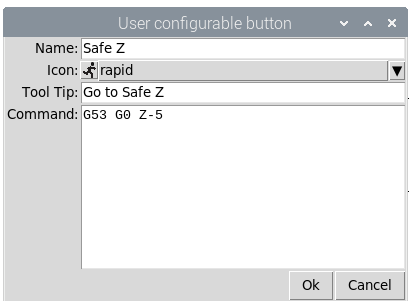

bCNC comes with a feature to move the spindle up to a safe z height. If you right-click on the “Safe Z” button it looks like this.

G90 G0Z(safe)The default is 3. In my case, it was 3 millimeters. I wouldn’t call that safe at all. I use clamps that are much thicker/taller than 3mm and most have bolts that stick up closer to 75mm. I had big trouble figuring how to change the definition of Z(safe). More importantly, I didn’t like the G90 in the code above. G90 relies on my working coordinate system. In my mind, the Safe Z should take the spindle as far up as possible. This happens to be an absolute positioning thing. I’ll back off 5mm just to be safe.

I entered this code in the Safe Z window

G53 G0 Z-5It should look like this.

Now when I press Z, no matter how stupidly I’ve set the working Z0 coordinate, I know the spindle will raise up to it’s maximum (almost).

- I use a homing cycle.

- I’m using mm for my units.

Adjust accordingly.