Getting a good, strong 3D print is a mess. Maybe another way of saying it is 3D printing with a CR-10 is a labor of love. I’m told the CR-10 is a capable machine. On good days it does what I need. I’m told something like the Prusa i3 requires substantially less tinkering, but then I find the occasional Youtube video where a person has a mess with those, too. It seems there is no 100% perfect solution.

Either way, I’m a tinkerer so here we go.

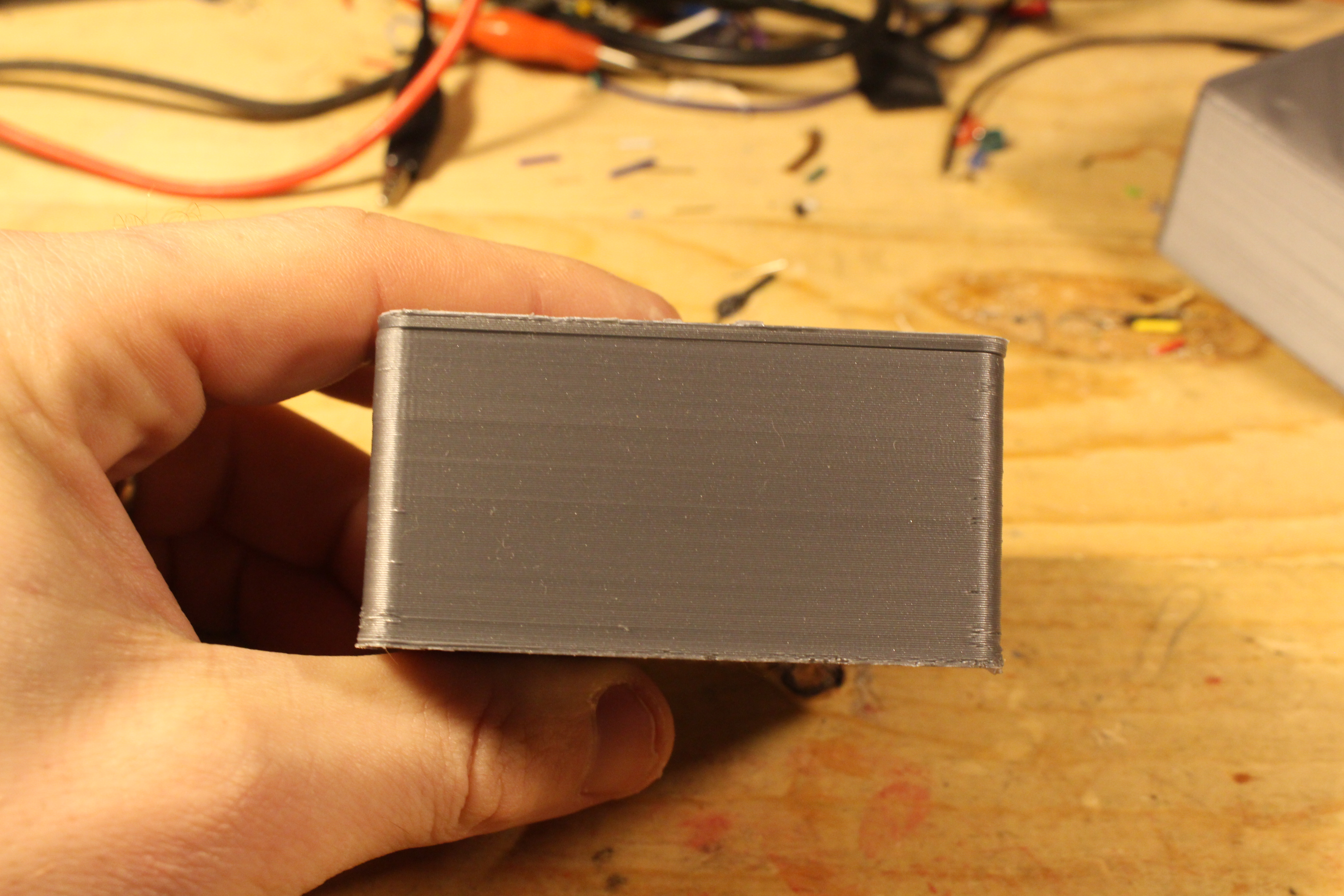

I was facing underextrusion on pretty much every print. The underextrusion wasn’t BAD and my picture of it isn’t great, either, but you could see missing lines from the print that should clearly be in there. Missing layers means the plastic didn’t get squirted where it was supposed to. It makes prints weak. I’m not overly concerned about the aesthetics, but that’s not ideal either.

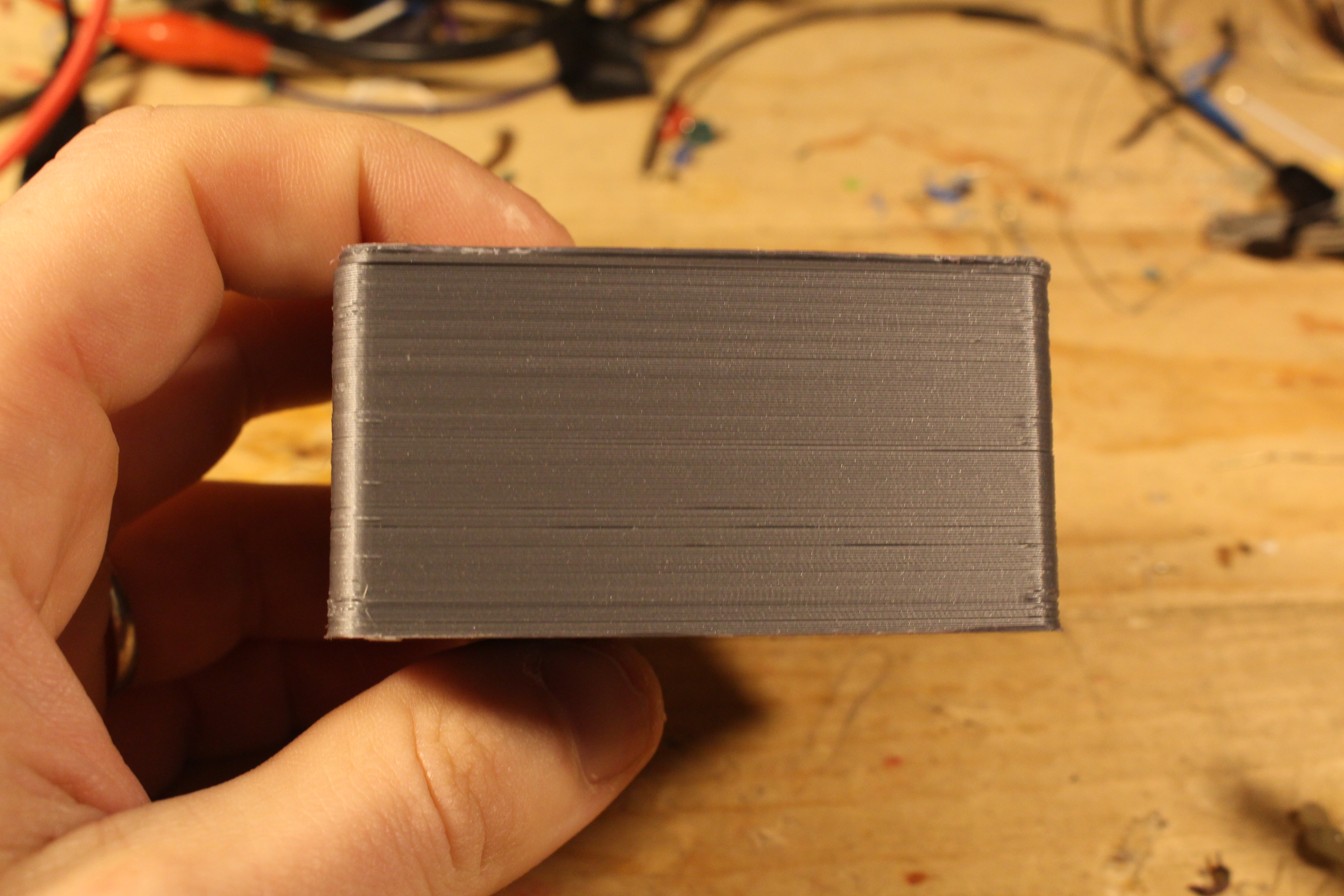

I picked up a $6 back of steel extrusion gears from Amazon that had much more aggressive teeth than my stock CR-10. My previous gear seemed kinda worthless and it had no shortage of ground-up PLA dust on it. Maybe cleaning that would have helped. I installed the new gear, recalculated my e-steps, and tossed the correct code into Cura. My very first print has zero underextrusion. Problem solved. That NEVER happens.

Note: Ignore the crunch edges. That’s the brim that suddenly became a real pain to get off a few weeks ago. It needs to be sanded off.

Before New Gear

After New Gear